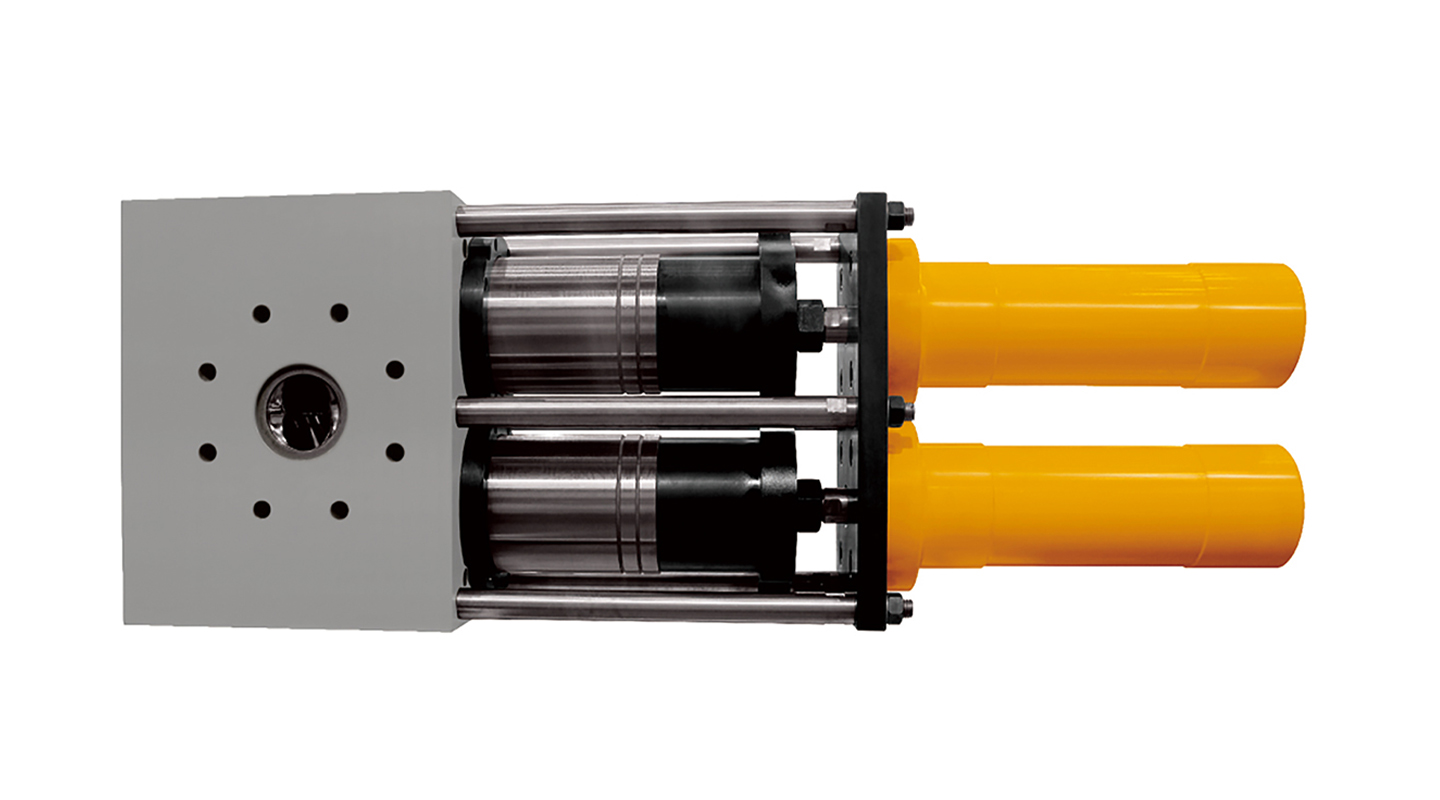

Dual-Column Dual-Station Fast Screen Changer Product Introduction / Product Introduction

The dual-column dual-station screen changer features a special sealing structure design and adopts a dual-flow-path, dual-screen design, allowing both screens to be used simultaneously. During screen changing, one screen works while the other is being replaced, without interrupting the material flow or production, truly achieving non-stop screen change. This improves product quality and meets customers' demands for higher production capacity and superior quality.

Dual-Column Dual-Station Fast Screen Changer Performance Features / Product Features

·Dual-flow-path design increases filtration area, meeting production requirements for higher output and better quality.

·Excellent sealing characteristics with rigid sealing, ensuring long service life.

·Features filling, venting, and purging functions to ensure product continuity during screen change.

·Can be specially designed and manufactured in various sizes and specifications according to user needs.

·Reasonable structural design, easy operation, and excellent performance.

Dual-Column Dual-Station Fast Screen Changer Application Range / Installation Instructions

The dual-column dual-station fast screen changer can be matched with production lines for various hot-melt adhesives, adhesives, coatings, and other compound products. It is used for material blending and filtration, especially suitable for the production of cast films, sheets, and plates, offering excellent performance, increased production, energy saving, and zero waste.

Dual-Column Dual-Station Fast Screen Changer Outline Drawing / Outline Drawing

The complete set of equipment includes Melt Pump, screen changer, inlet/outlet connectors, drive system, control system, etc. Customers can choose based on their specific situation. You can also contact Ruicheng Pump Industry's professional technical staff, Engineer Liu:18698063785. Based on your specific situation, we will recommend a suitable melt pump product for you.