| Features of RC-R Series Reactor Melt Metering Pump |

1. Low pressure and flow pulsation, enabling near-linear flow output, easy to control;

2. Excellent self-priming performance, applicable to vacuum inlet conditions (-0.05~-0.09MPa);

3. Suitable for high-temperature (≤350°C), medium-high pressure (≤15MPa), and high-viscosity (≤20,000Pa·s) conditions;

4.The equipment adopts a precision structural design, offering good operational accuracy and a long service life.

| Operating Parameters for RC-R Series Reactor Melt Metering Pump |

Conveyed Media Viscosity: 0.0003~40000 Pa·s

Inlet Pressure: -0.09~4 MPa

Outlet Pressure: ≤35 MPa

Operating Temperature: -50°C~350°C

| Melt Metering Pump Model Comparison Table for Polymer Reaction Processes |

Category/Code | Feature | Series | Pump Displacement (cc/r) | Operating Conditions

|

Viscosity (Pa·s) | Temperature (°C) | Inlet Pressure (MPa) | Outlet Pressure (MPa) | Capacity (m³/h) | Heating Method |

Bottom Pump RC-R | Small Displacement | R1 | 10~250 | 0.0003~40000 | -50~350 | -0.09~4 | ≤35 | 0.024~1.62 | Jacket |

| High Pressure | R2 | 315~38000 | 1~40000 | -50~350 | -0.09~4 | ≤35 | 0.9~102 | Jacket |

| Low Pressure | R3 | 315~38000 | 0.0003~40000 | -50~350 | -0.09~4 | ≤7 | 0.7~102 | Jacket |

R1: For reactor discharge under small flow, high viscosity, and high-pressure conditions. High self-priming, suitable for discharge from vacuum reactors. |

| R2: For reactor discharge under high viscosity and high-pressure conditions. High self-priming, suitable for discharge from vacuum reactors. |

| R3: For reactor discharge under low-pressure conditions. High self-priming, suitable for discharge from vacuum reactors. |

| Bottom Pump RC-R2 Series Models and Technical Parameters |

| Model | Displacement cc/r | Inlet Pressure (MPa) | Outlet Pressure (MPa) | Operating Temp. (°C) | Recommended Maximum Flow (m³/h) |

Low Viscosity Material < 50 Pa·s | Medium Viscosity Material (50~200 Pa·s) | High Viscosity Material (200~2000 Pa·s) | Ultra-High Viscosity Material > 2000 Pa·s |

| R2-315 | 315 | -0.09~4

| ≤35

| ≤350

| 2.3 | 1.5 | 0.9 | 0.7 |

| R2-500 | 500 | 3.2 | 2.2 | 1.2 | 0.9 |

| R2-750 | 750 | 4.9 | 3.2 | 1.8 | 1.4 |

| R2-1200 | 1200 | 6.5 | 4.5 | 2.6 | 2.3 |

| R2-1600 | 1600 | 8.6 | 6.0 | 3.5 | 3.0 |

| R2-2000 | 2000 | 10.8 | 7.6 | 4.3 | 3.8 |

| R2-2500 | 2500 | 12 | 8.1 | 4.7 | 4.1 |

| R2-4000 | 4000 | 15 | 10.8 | 7.6 | 6.5 |

| R2-6300 | 6300 | 20.4 | 17 | 10.2 | 9.2 |

| R2-8000 | 8000 | 21.6 | 17.3 | 13 | 11.7 |

| R2-12000 | 12000 | 32.4 | 25.9 | 18.1 | 16.2 |

| R2-25000 | 25000 | 67.5 | 54 | 37.8 | 33.8 |

| R2-38000 | 38000 | 102 | 82 | 57.4 | 51.3 |

| RC-R Series Reactor Melt Metering Pump Structural Materials |

Pump Body: Stainless Steel, Hastelloy, Monel Alloy

Gears: Nitriding Steel, Special Tool Steel, Straight/Helical Gears

Sliding Bearings: Tool Steel, Titanium Alloy, Silver-Nickel Alloy

Shaft Seal: Spiral Mechanical Seal

Seals: Mechanical Seal, Packing + Spiral Seal, Combined Seal with Flush Liquid

Heating Method: Electric Heating / Thermal Oil Heating

Specification Range: 5CC~38000CC

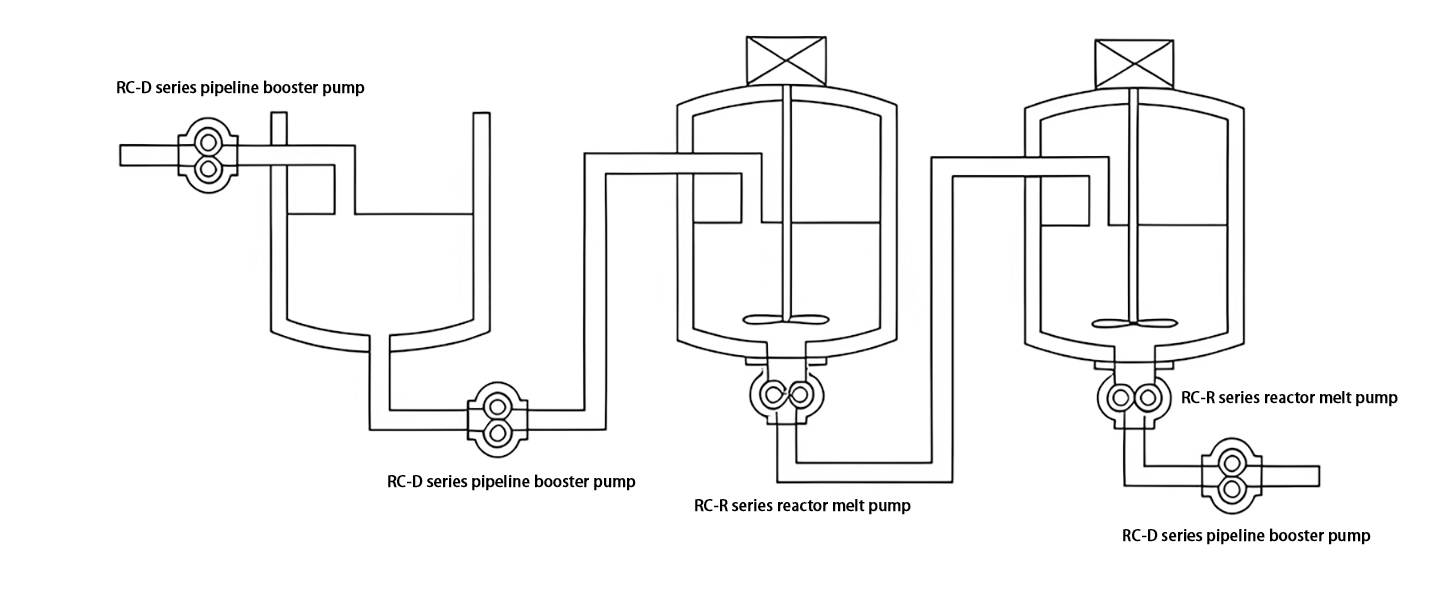

| RC-R Series Reactor Melt Metering Pump Installation Instructions |

The R Series ReactorMelt Metering Pump is generally installed below the reactor as a discharge pump, with the input shaft arranged horizontally.

The complete set of equipment includes the melt pump, inlet/outlet connections, drive system, control system, etc. Customers can select based on specific requirements. You can also contact Ruicheng Pump Industry's professional technical personnel, Engineer Liu:18698063785. Based on your specific situation, we can recommend a suitable melt pump product for you.