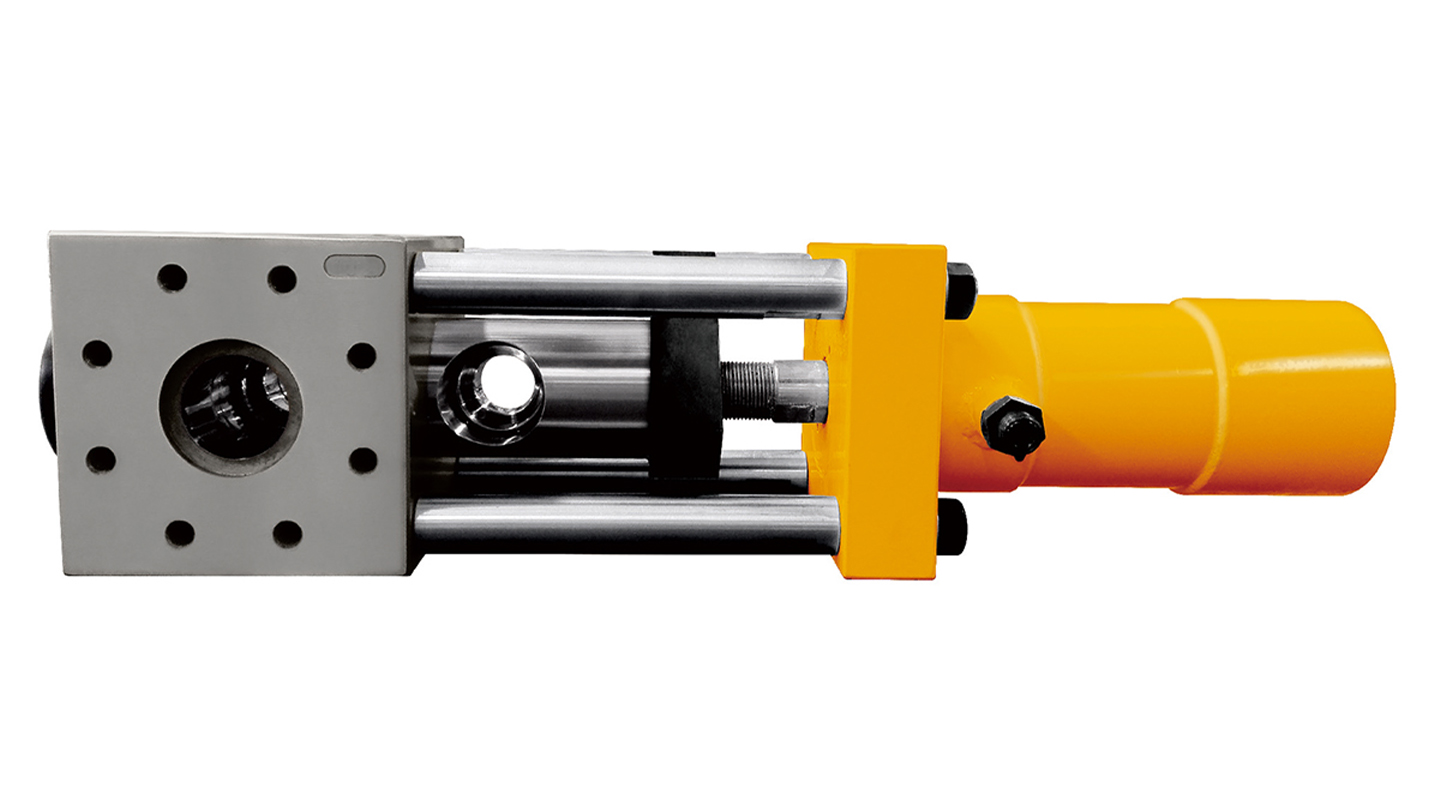

Single-Column Dual-Station Screen Changer Product Introduction / Product Introduction

The single-column screen changer features an integrated cylindrical screen changer body with characteristics of high temperature and high-pressure resistance. Manufactured from high-temperature alloy steel, it performs excellently in withstanding high temperatures and pressures. It utilizes dual filtration channels that work alternately, enabling rapid screen changes for convenient production and maintenance. It incorporates a highly wear-resistant and high-precision screen design. It maintains its performance under pressures of 30-50 MPa and temperatures of 300-400°C. Designed with a lead-in and venting structure, it allows for continuous screen changes without material leakage or production interruption, ensuring product continuity during screen replacement.

Single-Column Dual-Station Screen Changer Application Range / Product Features

The single-column dual-station screen changer is suitable for the production of high-pressure products, especially applicable to almost all thermoplastic materials, including blown film, cast film, biaxial orientation, fiber spinning, and pelletizing.

Single-Column Dual-Station Screen Changer Outline Drawing / Installation Instructions

The complete set of equipment includes Melt Pump, screen changer, inlet/outlet connectors, drive system, control system, etc. Customers can choose based on their specific situation. You can also contact Ruicheng Pump Industry's professional technical staff, Engineer Liu:18698063785. Based on your specific situation, we will recommend a suitable melt pump product for you.